At Sinco Gates, our custom design and quality of workmanship are what sets us apart. All our fabricators and welders are fully accredited with welding tickets, fully qualified with professional education and highly experienced. All our manufactured products are directly supervised by a fully qualified mechanical engineer with BSc in Engineering, MSc in Management, and over 12 years of experience in the field.

At Sinco Gates, we use raw material of high grades and standards. We select the raw material used in our products very carefully to ensure its strength and durability. Our suppliers are among the top in the market.

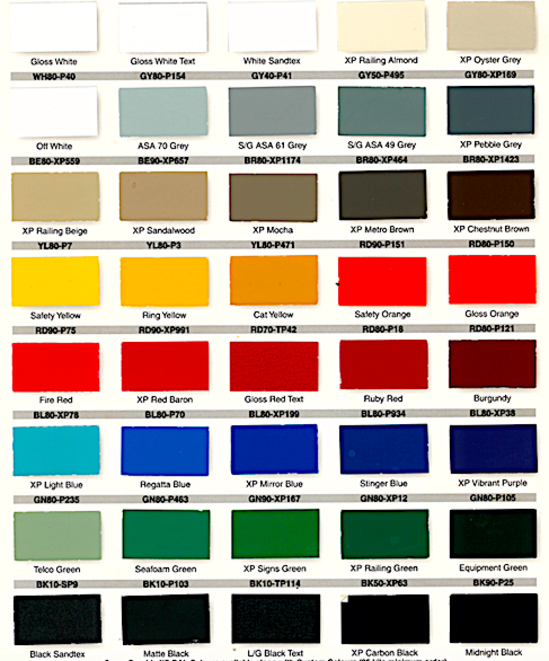

Our products are finished with high-quality commercial grade powder coating. We offer an expansive selection of powder coatings’ colours including black, white, dark brown, rideau brown, charcoal, grey, green, blue, red, yellow, etc.

Powder Coating:

Powder coating is a high-quality finish protecting the roughest, toughest machinery as well as some household items (e.g. Aerospace, Automobiles and bicycle frames, oil and gas pipelines, satellite dishes, heaters and furnaces, structural steel, aluminum doors and windows, etc).

Powder coating is applied to metal using a process called Electrostatic Spray Deposition (ESD), in which a spray gun is used to apply an electrostatic charge to the powder coating particles. After application of the powder coating, the metal parts enter a curing oven and subjected to heat until the coating chemically reacts to produce long molecular chains that are highly resistant to breakdown.

Advantages:

1. Powder coating provides more durable finish than liquid paints

2. Powder coating is more resistant to moisture, chemicals, ultraviolet light, and extreme weather conditions.

3. Powder Coating is more resistant to scratches, chipping, abrasion, corrosion or fading.

4. Powder Coating is more environmental friendly as it emits near zero volatile organic compounds (VOC).